추천 제품

생물학적 소스

synthetic

Quality Level

양식

liquid

기술

microbiological culture: suitable

점도

400 cP(lit.)

density

1.01 g/cm3 at 25 °C (lit.)

저장 온도

room temp

유사한 제품을 찾으십니까? 방문 제품 비교 안내

일반 설명

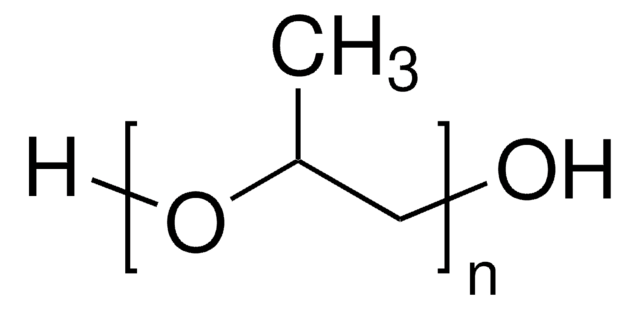

Antifoam function as an effective foam suppressor. Antifoam 204 contains 100% active components and is a mixture of organic non-silicone polypropylene-based polyether dispersions. It does not contain mineral oil. Antifoam 204 can itself be considered a surfactant, but it contains no other surfactants. This product is synthetic and not derived from animal or plant sources. Antifoam 204 can be sterilized repeatedly. The flow properties of Antifoam 204 are such that it can be pumped to a fermenter on an as-needed basis. For use in microbiological media, Sigma recommends a starting concentration of between 0.005% and 0.01%.

애플리케이션

Antifoam 204 has been used:

- to suppress bubbling in thylakoid solutions during intramembrane isoprene quantification

- as a component of fed-batch continuous culture fermentation medium

- to suppress severe foaming in fermenter

특징 및 장점

- Highly versatile surfactant for your cell biology and biochemical research

- Suitable for microbiological culture

기타 정보

Contains 100% active components and is a mixture of non-silicone organic defoamers in a polyol dispersion. Can be sterilized repeatedly.

For additional information on our range of Biochemicals, please complete this form.

Storage Class Code

10 - Combustible liquids

WGK

WGK 3

Flash Point (°F)

Not applicable

Flash Point (°C)

Not applicable

이미 열람한 고객

Physiology of Aspergillus niger in oxygen-limited continuous cultures: Influence of aeration, carbon source concentration and dilution rate

Diano A, et al.

Biotechnology and Bioengineering, 103(5), 956-965 (2009)

Ultrasound-assisted fermentation enhances bioethanol productivity

Sulaiman AZ, et al.

Biochemical Engineering Journal, 54(3), 141-150 (2011)

A novel noncovalent complex of chorismate mutase and DAHP synthase from Mycobacterium tuberculosis: protein purification, crystallization and X-ray diffraction analysis

M Okvist, et al.

Acta Crystallographica Section F, Structural Biology and Crystallization Communications, 65(10), 1048-1052 (2009)

Concentration of isoprene in artificial and thylakoid membranes

Harvey CM, et al.

Journal of Bioenergetics and Biomembranes, 47(5), 419-429 (2015)

Erin E Johnson et al.

Bioresource technology, 209, 1-7 (2016-03-08)

Waste crude glycerol from biodiesel production can be used to produce biobutanol using Clostridium pasteurianum with the main products being n-butanol, 1,3-propanediol (PDO) and ethanol. There has been much discrepancy and mystery around the cause and effect of process parameters

자사의 과학자팀은 생명 과학, 재료 과학, 화학 합성, 크로마토그래피, 분석 및 기타 많은 영역을 포함한 모든 과학 분야에 경험이 있습니다..

고객지원팀으로 연락바랍니다.